- Research on GFRTP Thermoforming Process based on Microstructure Analysis

Yao Zhong Xin*, Hyung Doh Roh*† , In Yong Lee**

*Department of Mechanical Engineering, BK21 FOUR ERICA-ACE Center, Hanyang University, Ansan 15588, Republic of Korea

**School of Mechanical Engineering, Dong-A University, Busan 38541, Republic of KoreaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This study aims to optimize the thermoforming process of Glass Fiber Reinforced Thermoplastics (GFRTP) by investigating the effects of temperature, pressure, stacking angle, and heating time. Systematic adjustments of these parameters enable a detailed microstructural analysis using optical microscopy. Python-based image analysis is employed to extract key quantitative features, such as void fraction, to support process optimization. Furthermore, an Artificial Neural Network (ANN) model is developed to predict optimal processing conditions. The ANN results identify conditions that minimize void fraction, demonstrating the effectiveness of the proposed optimization approach. This study provides a theoretical foundation for GFRTP manufacturing and introduces an innovative combination of image analysis and ANN modeling to enhance production efficiency and product quality, promoting broader composite applications.

Keywords: GFRTP, Python, Thermoforming, Thermoplastic composite

Glass Fiber Reinforced Thermoplastics (GFRTP) have gained increasing prominence in aerospace, automotive, and industrial applications due to their outstanding mechanical properties, recyclability, and lightweight nature [1]. As the demand for sustainable and high-performance materials rises, GFRTP is becoming a preferred alternative to traditional thermoset composites, offering significant advantages such as ease of processing, reduced cycle times, and potential for reusability [2].

However, the production of GFRTP with consistent quality presents several challenges, particularly in controlling void formation and fiber alignment during thermoforming. The manufacturing process must balance key factors such as cost, safety, and processing time to ensure efficiency and product reliability. The comparison between different characterization methods are listed in Table 1. Optimizing these factors is critical to reducing material waste, enhancing mechanical performance, and improving the scalability of production for industrial applications.

This study addresses these challenges by systematically analyzing the microstructural changes of GFRTP under varying thermoforming conditions. Using advanced image analysis techniques and an Artificial Neural Network (ANN) model, this research predicts optimal processing conditions to minimize void content while maintaining structural integrity. The combination of image-based microstructural evaluation and machine learning-based optimization presents a novel approach to improving GFRTP manufacturing efficiency. The findings of this study contribute to the ongoing development of thermoplastic composites, providing valuable insights for industry practitioners seeking to enhance production quality and reduce defects in GFRTP applications.

2.1 Materials

The GFRTP sheets used in this study are Celanese’s glass fiber-reinforced polypropylene (PP) prepreg tapes with a fiber content of 70%. Polypropylene is chosen as the matrix due to its excellent chemical resistance, low density, and recyclability, making it an ideal candidate for lightweight composite applications. Fiber-matrix interactions play a significant role in determining the overall mechanical behavior of thermoplastic composites [7].

2.2 Sample preparation

Multiple layers of prepreg tape are stacked and thermoformed using a hot press while varying only one of four conditions: temperature (T), pressure (P), forming time (t), or stacking angle (S). The samples are then cut into standardized dimensions for further characterization. The thermoforming process is conducted using a QMESYS’s QM900MA hot press as shown in Fig. 1.

|

Fig. 1 GFRTP Manufacturing Process Diagram |

3.1 Comparative Analysis of Characterization Methods

To ensure the reliability of GFRTP thermoforming, various characterization methods are utilized to assess material integrity, including non-destructive techniques such as Computed Tomography (CT) and C-Scan, as well as traditional destructive methods. The present study employs optical microscopy combined with Python-based image analysis to quantify void fraction and microstructural variations. A comparative evaluation of these techniques is presented in Table 1.

3.1.1 Advantages of Optical Microscopy and AI-Based Analysis

Compared to CT and C-Scan, optical microscopy offers high-resolution cross-sectional imaging, enabling detailed microstructural assessment of voids, fiber distribution, and defects. Unlike C-Scan, which primarily provides surface-level delamination and void fraction detection with limited depth resolution, optical microscopy allows for direct visualization of internal features at the microscale. CT, on the other hand, provides comprehensive 3D reconstruction of internal structures but requires complex equipment, extensive scanning times, and significant computational resources, making it less feasible for routine industrial applications.

The integration of AI-based image processing enhances the accuracy and efficiency of void fraction analysis. The Python-based approach automates image preprocessing, thresholding, and segmentation, minimizing human bias in void detection. Unlike traditional characterization techniques, the AI-assisted method not only quantifies void content but also correlates it with processing parameters, facilitating real-time optimization. This predictive capability is a distinct advantage over conventional methods, which are primarily used for post-process quality assessment rather than proactive optimization.

3.1.2 Limitations and Challenges

Despite its advantages, the proposed method has certain limitations. Unlike CT and C-Scan, which are inherently non-destructive, cross-sectional imaging via optical microscopy requires specimen preparation, involving embedding, polishing, and sectioning, which is time-consuming and material-intensive. Additionally, the accuracy of AI-based image analysis is dependent on the quality and consistency of the dataset used for training. Insufficient or biased training data may lead to inaccuracies in void fraction prediction.

Another challenge is that AI-driven analysis requires computational power and expertise in machine learning model development, which may not be readily available in all industrial settings. In contrast, C-Scan provides rapid, large-area scanning capabilities without the need for sample preparation, making it more suitable for in-line monitoring in production environments.

3.2 Polishing

The samples are vertically embedded in a 32 mm plastic mold and cured with epoxy resin. The cured specimens are then polished using sandpapers with grit sizes of 220, 400, and 1000 in sequential order, each for 3 minutes to obtain a smooth surface suitable for optical microscopy. A DreamTest’s GPM-1200N polishing machine is used for this process.

3.3 Visualization

Microstructural analysis is performed using an optical microscope at 200× magnification to capture high-resolution images of the fiber distribution and void fraction as shown as Fig. 2. Visualization microscopic images may exhibit slight variations in brightness, which can hinder the accurate detection of voids. Therefore, the acquired images are first processed using Python to normalize brightness levels as shown as Fig. 3. This preprocessing step enhances the visibility of voids, facilitating subsequent image analysis. The void fraction is determined by first loading the image using OpenCV functions and converting it into a grayscale image. Next, the image is binarized by applying a threshold to distinguish voids from the material. The number of pixels representing voids is then counted and expressed as a percentage of the total pixel count, yielding the void fraction. Finally, the results are visualized as shown as Fig. 4. The processed images clearly reveal the detected voids, ensuring accurate quantitative analysis.

3.4 ANN

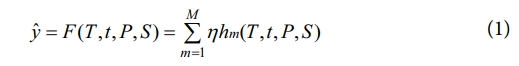

AI-based process optimization has been shown to significantly improve the efficiency and consistency of composite manufacturing [9]. Optimization of thermoforming parameters using deep learning provides a data-driven approach to improving GFRTP processing [11]. Machine learning techniques, including ANN, have been increasingly applied in composite manufacturing to predict and optimize processing conditions [3]. Optimization of Processing Parameters To identify the optimal processing parameters that minimize void fraction, a Gradient Boosting Regression (GBR) model is employed. The model takes four input variables—temperature (T), pressure (P), time (t), and stacking angle (S)—and maps them to the predicted void fraction(Fig. 5):

where hm represents the prediction of the mth regression tree, η is the learning rate, and M is the number of trees.

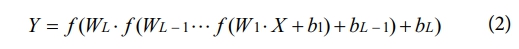

Additionally, the ANN model used in this study consists of multiple hidden layers, where each layer contains a set number of nodes that contribute to learning the complex nonlinear relationship between processing parameters and void fraction. The general structure of the ANN can be represented as:

Where Wl and bl are the weights and biases of the lth layer, and f represents the activation function.

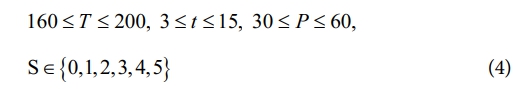

To further optimize the process, Differential Evolution (DE) is applied to minimize F(T, t, P, S), ensuring that the processing conditions yield the lowest void fraction. The optimization follows:

subject to the constraints:

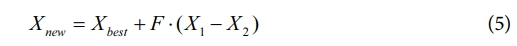

DE iteratively updates processing parameters based on the following mutation equation:

where Xbest is the best parameter set found so far, X1 and X2 are randomly chosen parameter sets, and F is a scaling factor. The final optimal conditions (T*, t*, P*, S*) correspond to the minimal predicted void fraction, improving process reliability and composite quality.

|

Fig. 2 Raw cross-sectional images of GFRTPs |

|

Fig. 3 Pre-proccessed images of the GFRTPs using Python |

|

Fig. 4 Flowchart of Void Visualization |

|

Fig. 5 ANN Flowchart |

4.1 Image

Experimental and numerical studies on void evolution in thermoplastic composites reveal the importance of process control [10]. The role of fiber orientation in determining the mechanical properties of GFRTP has been widely investigated [12]. Predictive modeling of void content in thermoplastic composites aids in optimizing manufacturing conditions [13]. Optical Microscopy images reveal variations in fiber alignment and void fraction content across different thermoforming conditions. High temperatures improve resin flow but may lead to fiber misalignment as shown as Fig. 6. Fig. 7

4.2 Variables

Temperature, pressure, and time significantly influence void formation [4]. Influence of pressure on void formation in thermoformed composites has been extensively studied, highlighting its effect on final product quality [8]. An optimal processing window is identified based on the ANN-predicted results.

4.3 Quality

Various strategies have been developed to minimize void content in thermoforming processes, emphasizing the importance of precise control over temperature, pressure, and fiber arrangement [5]. Quantitative analysis indicates that excessive temperature results in resin degradation, while insufficient pressure leads to poor fiber wetting, affecting mechanical properties.

4.4 Optimization

Effect of process variables on the mechanical performance of GFRTP has been studied to optimize the structural integrity of the final product [14]. The ANN model accurately predicts processing conditions that minimize void fraction while maintaining mechanical integrity, demonstrating its applicability in process optimization. The optimal production parameters identified are 161oC, 3 min, 31 bar, and a stacking sequence of [0]8. Under these conditions, the minimum void fraction achieved is 0.23947%. The performance of the ANN model is evaluated, yielding a mean square error (MSE) of 0.00014 and an R2 value of 0.4319, indicating moderate predictive accuracy.

Recent studies have demonstrated the potential of AI-driven models in optimizing fiber orientation and processing conditions for thermoplastic composites [6]. The validation of the Artificial Neural Network (ANN) model was conducted by comparing the ANN-predicted optimal processing parameters with the experimentally determined optimal conditions. The results revealed a strong correlation between the two, indicating the model’s capability to accurately predict thermoforming conditions that minimize void fraction. The ANN model identified the optimal combination of temperature, pressure, stacking sequence, and heating time with minimal deviation from the experimental values, demonstrating its practical applicability in GFRTP processing.

This agreement between ANN predictions and experimental results highlights the reliability of the proposed ANN-based optimization approach. By leveraging microstructural analysis and data-driven learning, the model successfully captures the complex relationships between processing parameters and void formation. These findings suggest that the ANN model can serve as an efficient tool for process optimization, reducing the reliance on extensive trial-and-error experiments. Future enhancements, such as expanding the training dataset and incorporating additional microstructural features, could further refine its predictive accuracy, leading to more robust and consistent GFRTP manufacturing processes.

|

Fig. 6 Void Visualization results |

|

Fig. 7 Cross sectional analysis chart (All other conditions remain unchanged, with only the stacking angle varied to fabricate the GFRTP. Images are captured from the left, center, and right regions of the cross-section for image analysis, and the average porosity is determined.) |

This study presents a comprehensive analysis of the thermoforming process for GFRTP using microstructural evaluation and ANN-based modeling. The findings highlight the critical role of processing parameters in achieving defect-free components. The optimal processing parameters—161oC, 3 min, 31 bar, and a stacking angle of [0]8—result in a minimum void fraction of 0.23947%, demonstrating the effectiveness of the proposed optimization approach. The ANN model provides a predictive framework for optimizing GFRTP thermoforming conditions.

One of the key advantages of this research is the integration of microstructural analysis with ANN modeling, enabling a systematic and data-driven approach to process optimization. This methodology significantly reduces the reliance on trial-and-error experimentation, improving production efficiency while minimizing material waste. Additionally, the findings support the broader industrial adoption of GFRTP by enhancing process reliability and repeatability. Future research will focus on expanding the ANN database and further optimizing the ANN model to enhance its predictive capabilities, allowing for accurate porosity predictions based on specified temperature, pressure, stacking angle, and heating time. This enhancement will contribute to a more refined manufacturing process and higher-quality GFRTP products.

Future research will focus on expanding the ANN database and further optimizing the ANN model. The goal is to enable accurate void fraction predictions for GFRTP production based on specified temperature, pressure, stacking angle, and heating time. This enhancement will improve the predictive capability of ANN, contributing to a more refined manufacturing process and higher-quality GFRTP products. Additionally, Further experimental validation using mechanical testing will be conducted to correlate microstructural quality with mechanical performance.

This research was supported by Korea Institute for Advancement of Technology(KIAT) grant funded by the Korea Government(MOTIE) (RS-2024-00409639, HRD Program for Industrial Innovation).

- 1. Smith, R., and Johnson, P., “Mechanical properties of hybrid fiber reinforced thermoplastics,” Functional Composites and Structures, Vol. 28, No. 4, 2020, pp. 315-330.

- 2. Kim, H., and Lee, D., “Advanced processing techniques for thermoplastic composites,” Composites Research, Vol. 34, No. 2, 2021, pp. 112-120.

- 3. Brown, T., and Williams, L., “Machine learning approaches in composite manufacturing,” Functional Composites and Structures, Vol. 29, No. 2, 2021, pp. 155-170.

- 4. Zhao, Y., and Kim, H., “Thermoplastic composite processing under variable pressure conditions,” Functional Composites and Structures, Vol. 30, No. 1, 2022, pp. 45-60.

- 5. Lee, M., and Yoon, K., “Void reduction strategies in thermoforming of GFRTP,” Composites Research, Vol. 36, No. 3, 2023, pp. 201-210.

- 6. Park, J., and Choi, S., “Optimization of fiber orientation in thermoplastic composites using AI models,” Composites Research, Vol. 35, No. 1, 2022, pp. 89-98.

- 7. Wang, F., and Zhang, Y., “Fiber-matrix interactions in thermoplastic composites,” Composite Structures, Vol. 220, 2019, pp. 150-162.

- 8. Liu, C., and Chen, T., “Influence of pressure on void formation in thermoformed composites,” Journal of Thermoplastic Composite Materials, Vol. 34, No. 5, 2021, pp. 403-415.

- 9. Patel, M., and Singh, R., “AI-based process optimization in composite manufacturing,” Materials Today: Proceedings, Vol. 42, 2020, pp. 2256-2268.

- 10. Roberts, L., and Kim, J., “Experimental and numerical studies on void evolution in thermoplastic composites,” Polymer Composites, Vol. 43, No. 7, 2022, pp. 3124-3138.

- 11. Han, S., and Park, Y., “Optimization of thermoforming parameters using deep learning,” Composites Science and Technology, Vol. 210, 2023, pp. 108842.

- 12. Thompson, B., and Wilson, D., “Role of fiber orientation in mechanical properties of GFRTP,” Advanced Composites and Hybrid Materials, Vol. 3, No. 4, 2020, pp. 562-574.

- 13. Yoshida, K., and Tanaka, H., “Predictive modeling of void content in thermoplastic composites,” International Journal of Material Forming, Vol. 14, No. 3, 2021, pp. 723-738.

- 14. Choi, W., and Kang, H., “Effect of process variables on the mechanical performance of GFRTP,” Composites Part A: Applied Science and Manufacturing, Vol. 152, 2022, pp. 106695.

This Article

This Article

-

2025; 38(2): 80-85

Published on Apr 30, 2025

- 10.7234/composres.2025.38.2.080

- Received on Feb 25, 2025

- Revised on Mar 14, 2025

- Accepted on Mar 25, 2025

Services

Services

- Abstract

1. introduction

2. experimental

3. characterization

4. results

5. conclusions

6. future works

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Hyung Doh Roh

-

Department of Mechanical Engineering, BK21 FOUR ERICA-ACE Center, Hanyang University, Ansan 15588, Republic of Korea

- E-mail: rhd1213@hanyang.ac.kr

Copyright ⓒ The Korean Society for Composite Materials. All rights reserved.

Copyright ⓒ The Korean Society for Composite Materials. All rights reserved.